The 10 best metrics for operations managers

Why use metrics for operations managers?

Metrics are essential for operations managers because they provide quantifiable data that can be used to assess the effectiveness and efficiency of business processes. By using metrics, operations managers can identify areas for improvement, track progress over time, and make informed decisions based on objective data. Metrics also help in aligning the operations with the overall strategic goals of the organisation. Whether it's improving production efficiency, reducing costs, or enhancing customer satisfaction, having the right metrics in place allows operations managers to focus their efforts on the most impactful areas.

The top 10 metrics for operations managers

1. Overall Equipment Effectiveness (OEE)

OEE is a comprehensive metric that evaluates how effectively a manufacturing process is utilised. It takes into account the availability, performance, and quality of equipment, helping operations managers to pinpoint inefficiencies.

- How OEE is calculated: OEE is calculated by multiplying Availability (percentage of scheduled time equipment is operating), Performance (speed at which equipment operates as a percentage of its designed speed), and Quality (percentage of good parts produced).

- What tools can be used to get OEE data: Tools such as SensrTrx, UpKeep, and MachineMetrics can be used.

- What average, good, and best in class look like for OEE: Average OEE is around 60-70%, good OEE is 80-85%, and best in class is 90% and above.

2. First Pass Yield (FPY)

FPY measures the percentage of products that are manufactured correctly and to specifications the first time through the production process, without needing any rework.

- How FPY is calculated: FPY is calculated by dividing the number of good units produced by the total number of units going through the production process.

- What tools can be used to get FPY data: Tools such as Tableau, SAP Quality Management, and Qlik can be used.

- What average, good, and best in class look like for FPY: Average FPY is around 85%, good FPY is 90-95%, and best in class is above 95%.

3. Cycle Time

Cycle time refers to the total time from the beginning to the end of a process, which is important for understanding the throughput and efficiency of your operations.

- How cycle time is calculated: Cycle time is calculated by measuring the start and end time of a process and taking the difference between the two.

- What tools can be used to get cycle time data: Tools such as LeanKit, Asana, and JIRA can be used.

- What average, good, and best in class look like for cycle time: Benchmarking for cycle time varies widely depending on industry and product, but reducing it by even a small percentage can be significant.

4. On-Time Delivery (OTD)

OTD measures the percentage of units delivered on or before the promised date, and is crucial for customer satisfaction and operational efficiency.

- How OTD is calculated: OTD is calculated by dividing the number of units delivered on or before the promised date by the total number of units delivered.

- What tools can be used to get OTD data: Tools such as Oracle SCM, SAP SCM, and Epicor can be used.

- What average, good, and best in class look like for OTD: Average OTD is around 85-90%, good OTD is 95%, and best in class is 98% and above.

5. Inventory Turnover

Inventory turnover measures how often inventory is sold and replaced over a specific period. This helps in efficiency and cash flow management.

- How inventory turnover is calculated: Inventory turnover is calculated by dividing the cost of goods sold by the average inventory.

- What tools can be used to get inventory turnover data: Tools such as NetSuite, QuickBooks, and Fishbowl Inventory can be used.

- What average, good, and best in class look like for inventory turnover: Average inventory turnover is 5-6 times per year, good is 8-9, and best in class is 10 and above.

6. Cost Per Unit

Cost per unit measures the cost incurred by a company to produce one unit of product. It helps identify cost-saving opportunities and efficiency improvements.

- How cost per unit is calculated: Cost per unit is calculated by dividing the total cost of production (including fixed and variable costs) by the number of units produced.

- What tools can be used to get cost per unit data: Tools such as Excel, SAP Business ByDesign, and Sage.

- What average, good, and best in class look like for cost per unit: This can vary widely based on industry and product but reducing your cost per unit by any amount is beneficial.

7. Scrap Rate

Scrap rate measures the percentage of materials that are discarded during the production process. Lowering the scrap rate can lead to significant cost savings and efficiency improvements.

- How scrap rate is calculated: Scrap rate is calculated by dividing the weight or number of rejected materials by the total weight or number of materials produced, and then multiplying by 100.

- What tools can be used to get scrap rate data: Tools such as Manufacturing ERP software, Minitab, and SPC for Excel.

- What average, good, and best in class look like for scrap rate: Average scrap rate is around 3-5%, good is 2-3%, and best in class is below 1%.

8. Capacity Utilisation

Capacity utilisation measures how much of your total available capacity is actually being used. This is important for understanding how well resources are being utilised.

- How capacity utilisation is calculated: Capacity utilisation is calculated by dividing actual output by potential output and then multiplying by 100.

- What tools can be used to get capacity utilisation data: Tools such as Capacity, Smartsheet, and Odoo can be used.

- What average, good, and best in class look like for capacity utilisation: Average capacity utilisation is around 70-75%, good is 80-85%, and best in class is 90% and above.

9. Downtime

Downtime measures the amount of time equipment is not in operation. Tracking downtime is crucial for identifying causes of stoppages and areas for improvement.

- How downtime is calculated: Downtime is calculated by measuring the total time equipment is not operational within a specific period.

- What tools can be used to get downtime data: Tools such as MaintainX, Fiix, and PEMAC can be used.

- What average, good, and best in class look like for downtime: Average downtime can vary significantly by industry, but reducing downtime by even a small percentage can result in significant productivity gains.

10. Order Fulfilment Cycle Time (OFCT)

OFCT measures the average time taken to fulfil customer orders, from the time the order is received till it is shipped. This helps improve customer satisfaction and operational efficiency.

- How OFCT is calculated: OFCT is calculated by measuring the time interval from order receipt to shipment for each order, then averaging this time.

- What tools can be used to get OFCT data: Tools such as ShipStation, TradeGecko, and Brightpearl can be used.

- What average, good, and best in class look like for OFCT: This can vary widely, but for e-commerce, an average OFCT is 2-3 days, good is 1 day, and best in class is same-day shipping.

How to track metrics for operations managers

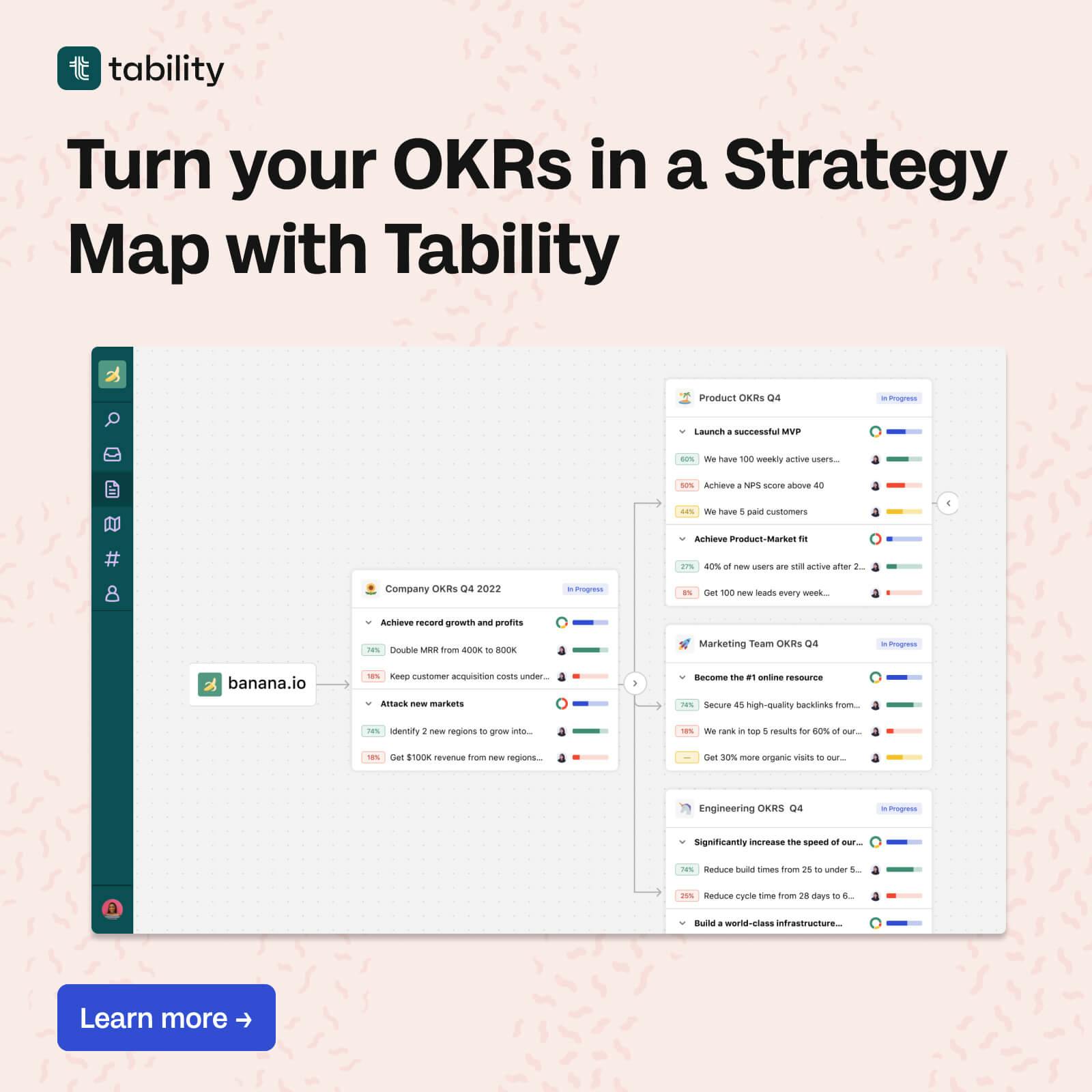

To effectively track metrics for operations management, consider using a goal-tracking tool like Tability. Tability can save you time and help your team stay focused on the right metrics to improve. Tability allows you to set KPIs, track progress, and gain insights through visual data representations, thereby enabling more informed decision-making.

FAQ

Q: What are KPIs and why are they important? A: KPIs (Key Performance Indicators) are measurable values that demonstrate how effectively an organisation is achieving key business objectives. They are important because they provide focus for strategic and operational improvement, and help in decision-making by providing valuable data.

Q: How often should I review my metrics? A: The frequency of review depends on the specific metric and its relevance to your operations. However, a general rule of thumb is to review operational metrics at least monthly, and more frequently for metrics that have significant impact on day-to-day operations.

Q: What is the first step in implementing these metrics? A: The first step is to clearly define your business objectives and align your metrics with these objectives. Ensure you have the necessary tools and processes in place to accurately collect and analyse data for each metric.

Q: Can Tability integrate with other software? A: Yes, Tability can integrate with a variety of other software tools to sync data and provide a more streamlined tracking and reporting process. Check Tability's integrations page for more details.

Q: What should I do if my metrics are below average? A: If your metrics are below average, the first step is to identify the root causes of the underperformance. Then, develop a plan to address these issues. Implement continuous monitoring and adjust your approach as needed to improve over time.

By focusing on these top 10 metrics and consistently tracking them, operations managers can drive significant improvements in efficiency, performance, and overall business outcomes.